Founded in 2003 by a team of professional engineers experienced in the electrical and electronic hardware and software industries, SafeTest has established itself as a leader in the field.

Our initial success came from winning the European repair contract for Parker Hannifin's motion and control products, which set a solid foundation for our rapid diversification into electronic contract manufacturing and electronic design.

At SafeTest, we pride ourselves on our ability to respond quickly to clients' needs and tailor our services to meet their specific requirements. This customer-centric approach has enabled us to build a reputation for delivering reliable solutions across the Medical, Military, Aviation, and numerous other industries for over 20 years.

We offer a complete PCB assembly and manufacturing service, capable of handling projects of all scales. Our expertise covers full design and production services for PCBs, looms, harnesses, cabinets, and more. We work with customers from concept to completed product, managing projects at any stage, from inception to completion and delivery.

If you have any inquiries or require further information, please don't hesitate to get in touch with us.

MEET The TEam

Brief overview

Friendly support

Our support team is here to ensure everything runs smoothly, allowing you to focus on other priorities. You will also have a dedicated key account manager as your point of contact, familiar with your product and specific needs.

Full Design Service:

Safetest Ltd offers end-to-end solutions for PCBs, looms, harnesses, box-build and test equipment.

PCB Prototyping

Explore our budget-friendly PCB prototyping solution, complete with a complimentary Design for Manufacture review (DFM).

3D Printing

Utilising our in-house SLA 3D printer, we provide a quick and cost-effective prototype service for all your enclosure needs.

Full Procurement

Our comprehensive procurement service, built on solid relationships with key suppliers, ensures traceability, transparency, and reliability throughout the procurement process.

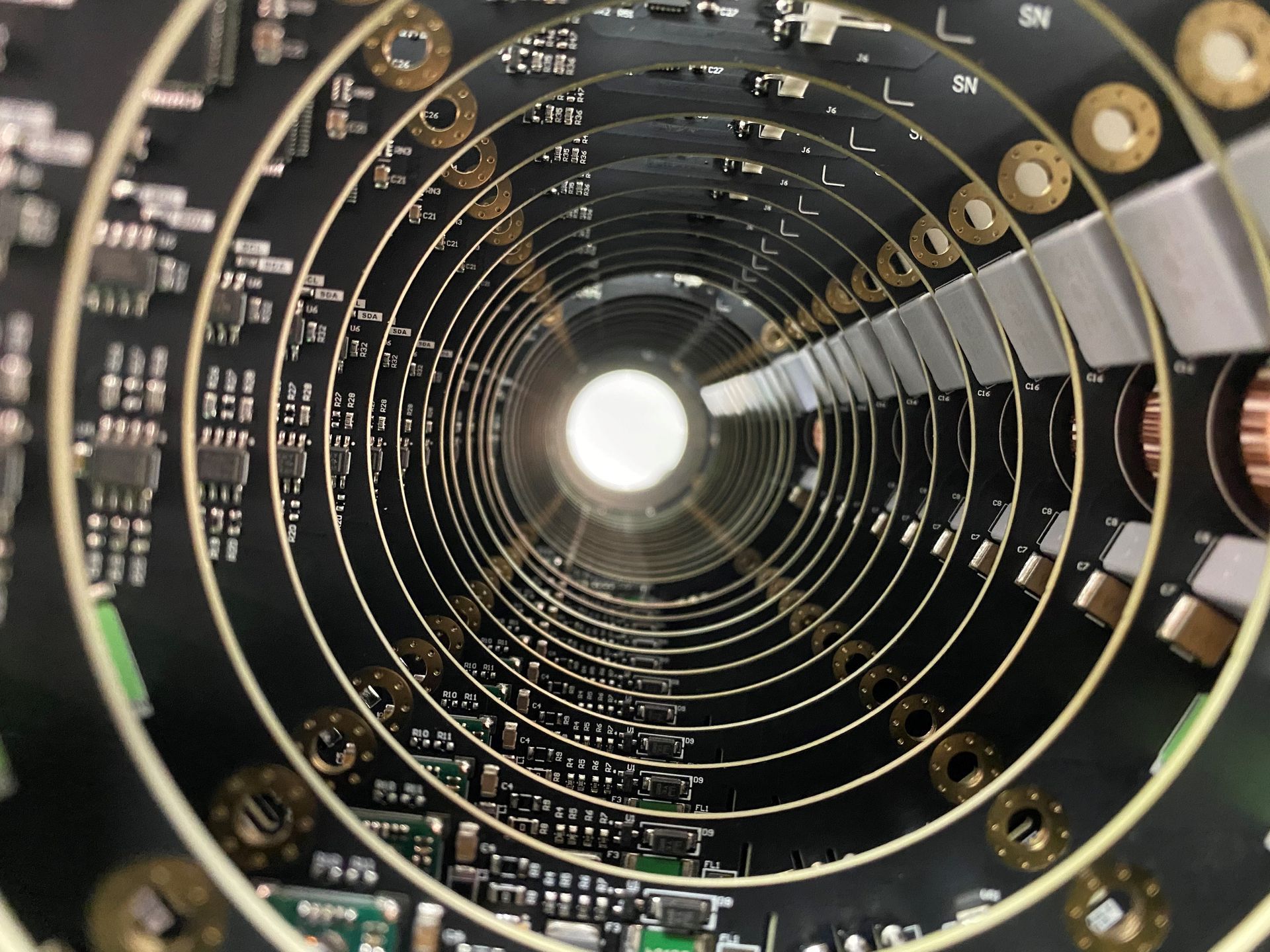

Comprehensive PCB Assembly Services

Complete solutions for PCB assembly, accommodating projects of all sizes. We operate two surface mount lines and have skilled staff trained in IPC610 standards for surface-mount, through-hole assembly and inspection.

Automated Optical Inspection (AOI)

Harnessing state-of-the-art technology, our AOI system ensures a highly accurate inspection method for PCB assemblies

Top Level Assembly Services

We offer a box build service, assembling final products that range from basic enclosures to intricate designs involving multiple PCBs. We excel in producing premium-grade cable assemblies and wiring looms.

Test

We can offer full testing capabilities, assuring the quality and reliability of every component. We can also design and build bespoke testing equipment for your product needs.

KANBAN

Unlock efficiency and cost savings with our KANBAN system, tailored for your needs. This system minimising the risk of delays caused by out-of-stock items and lowering transportation costs. We reduce extra processing of smaller orders, resulting in cost reductions that we pass on to you.

KEY EQUIPMENT

Europlacer iineo

- SMT pick and place machine

- Components range from 01005 to 50mm x 50mm.

- 264 feeder positions.

- 10 matrix trays.

- Placement rate up to 15,390 components per hour.

- Maximum board size 1610mm x 600mm.

- Maximum component height 34mm.

- Electrical component testing.

- Placement Accuracy 22um (QFPS) TO 46um (CHIPS)

Europlacer iiA1

- SMT pick and place machine

- Components range from 01005 to 50mm x 50mm.

- 164 feeder positions.

- 2 matrix trays.

- Placement rate up to 15,390 components per hour.

- Maximum board size 1070mm x 715mm.

- Maximum component height 34mm.

- Electrical component testing.

- Placement Accuracy 22um (QFPS) TO 46um (CHIPS)

Aleader ALD 515

Automated Optical Inspection (AOI) to meticulously inspect PCBs both before and after the reflow process, ensuring precise and accurate component placement.

100% inspection coverage, all components are inspected for all types of the defects: missing, misalignment, billboard, up-side-down, tombstone, damaged, wrong component, lifted leads, open, insufficient / excessive solder, shorts, polarity, solder balls

Form 3+ 3D Printer

- Stereolithography (SLA) resin 3D Printer

- Rapid print speeds

- Industry-leading accuracy

- Specialized materials offer UV stability, flame retardancy, ESD resistance, glass-filled rigidity, biocompatibility, and more.

- Max Build Size - 145mm (w) x 145mm (d) x 193mm (h)

QUALITY STANDARDS

ISO 9001:2015

Safetest Ltd adheres to the highest industry standards, proudly holding ISO9001 certification, demonstrating our commitment to quality management.

IPC-A-610

At SafeTest, we adhere to the IPC-A-610 standard, ensuring the highest quality and reliability in our electronic assemblies. This commitment to industry-leading practices guarantees that our products meet rigorous performance and safety criteria, providing our clients with exceptional results every time.